Our ProductsOur Products

- Centralized up to 1MLD WTP for Water Supply Schemes

- Decentralized up to 100 KLD WTP for Community

- Compact WTP for Domestic & School use

- IoT for Monitoring & controlling

High Flow Water Supply Scheme based Water Treatment Plant for Iron/Arsenic/Fluoride/Uranium removal

About AMRIT TECHNOLOGY FOR Fluoride removal

With the advent of nanotechnology, it is possible to address contaminants such as fluoride at affordable cost. AMRIT delivers drinking water below 1 ppm. The composition for arsenic removal is composed of nanoscale metal oxyhydroxide. Particle size below a critical limit increases the number of surface atoms substantially leading to higher surface energy. An important aspect is to ensure that such nanoparticles are strongly anchored onto solid surfaces so as to make sure that they don’t leach into water and adsorbed fluoride doesn’t get released from the composition. The composition can handle up to an input load of 10 ppm of fluoride. Composition is at least 5-6 times more efficient than most competitive adsorbent available currently. Since the contact time required for removal is fairly low, the composition used is granular in nature, thereby offering negligible pressure drop. This helps from several aspects: treatment cost reduces, filtration unit becomes smaller, can operate with minimum pressure and easily maintainable by local community and at the end reduces sludge quantity.

ADDITIONAL TREATMENT UNITS WITHIN FRU DESIGN

AIRON REMOVAL UNIT

The technology for iron removal, developed at IIT Madras removes the colloidal particles of Fe(OH)3 through adsorption, instead of filtration. It is capable of removing colloidal iron in all size ranges. the composition can handle any concentration of colloidal iron, even reaching up to 50 ppm. The composition can remove iron from water without requiring frequent backwash. Composition offers extremely high adsorption kinetics, thereby requiring minimal contact time for iron removal. This helps from several aspects: treatment cost reduces, filtration unit becomes smaller, filtration unit can be operated with minimum pressure and maintenance.

OXIDATION UNIT

The purpose of the oxidation unit is to provide pre-treatment by mixing of compressed air with influent water. Air flow to water flow is counter current type. Oxidation unit has provision for an air vent valve, so that a passage is provided for air to exist the vessel. Material of construction used for the oxidation unit is mild steel

POLISHING UNIT

Polisher unit based on pressure vessel design, the purpose is to provide a requisite depth of improving the taste of the water (as the source of the water is groundwater). Material of construction used for the polishing unit is mild steel

BACKWASH WATER TREATMENT UNIT

Backwash water treatment unit is provided to collect the backwash water from all the vessels. Backwash water is filtered through sand, gravel, and pebble bed by gravity. The clear water is used for gardening purpose. This treatment unit is provided to ensure that fine particles in raw water which are retained on our pre-filter, is backwashed and retained in the backwash treatment unit. The safe disposal of the backwash water is critical for maintaining the underground water quality.

Handpump-operated water filters are a practical solution for areas with limited access to electricity or during emergencies. They work by manually pumping water through a filtration system, which often includes activated carbon and other materials to remove impurities and improve water quality.These filters are ideal for providing safe drinking water in remote or disaster-affected areas.

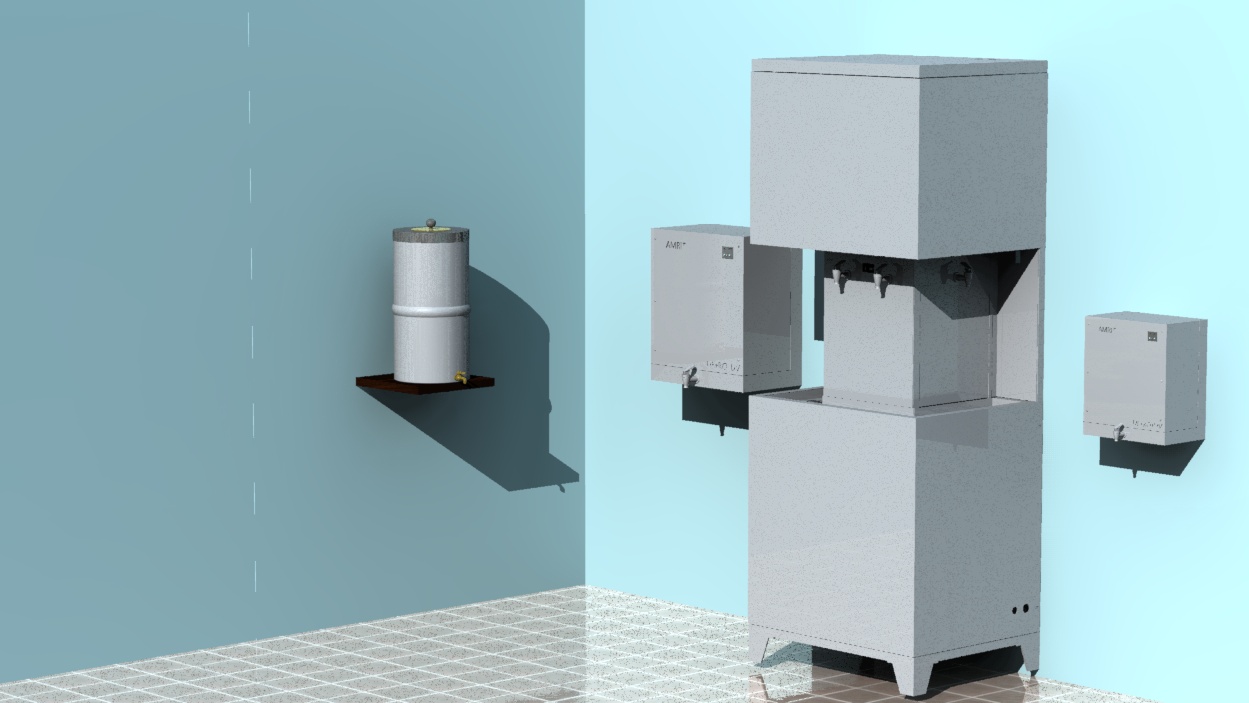

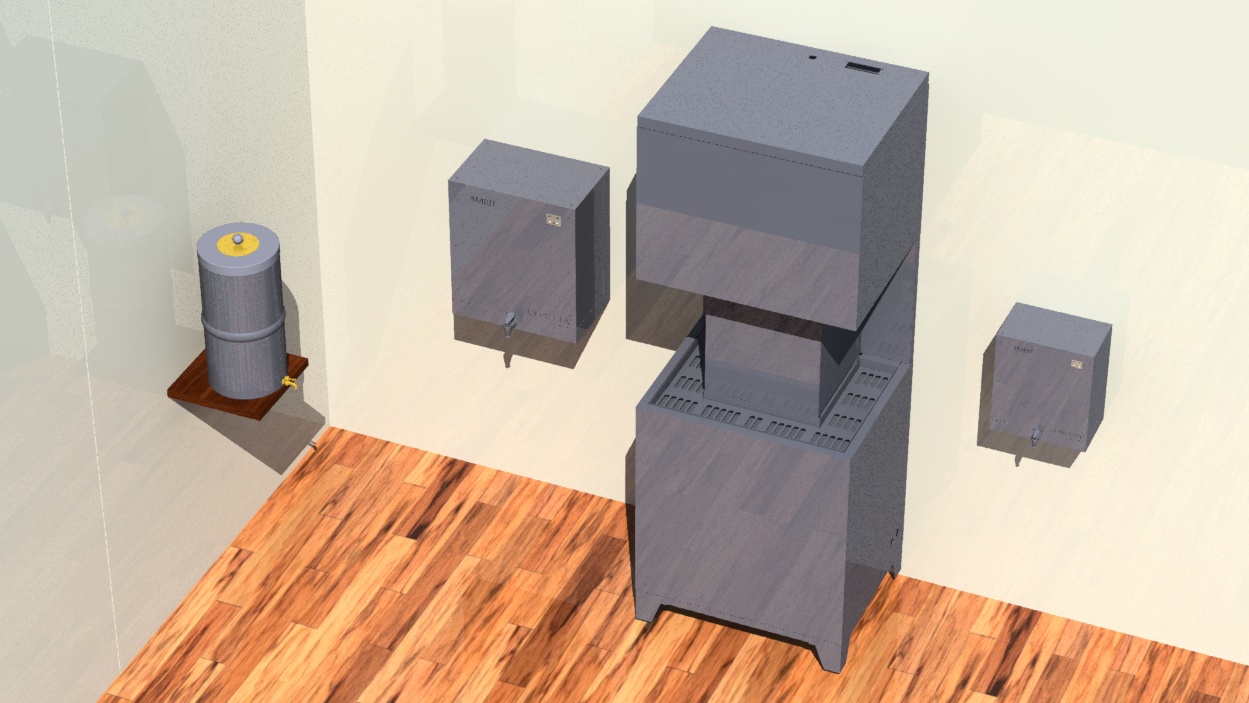

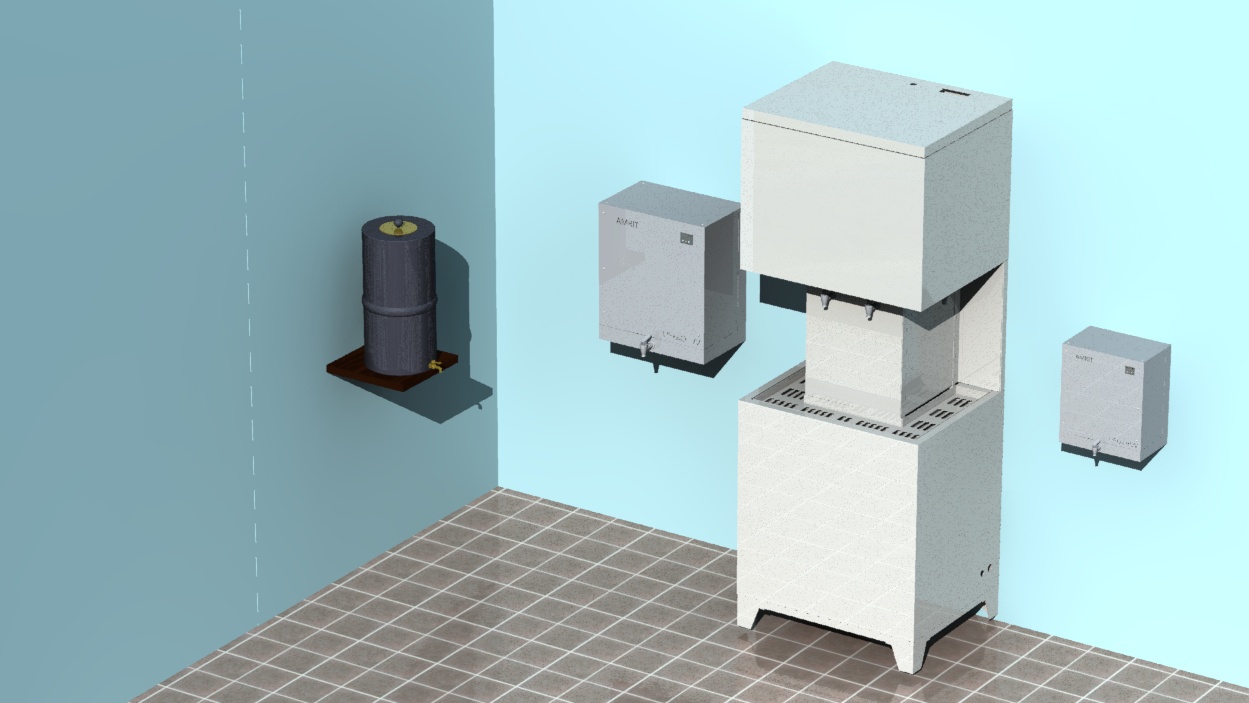

A community-operated iron removal plant with a capacity of 100kLD (100,000 liters per day) is a large-scale solution for treating water with high iron content. These plants are typically designed to remove iron from groundwater or other sources, making the water safe for drinking and domestic use.These plants are ideal for rural or semi-urban areas where iron contamination is a common issue. They are designed to be user-friendly, requiring no skilled operators, chemical additions, or electricity.

Community-operated water treatment plants are centralized facilities designed to provide clean and safe water to a group of households or an entire community. These plants can address various water quality issues, such as removing contaminants, treating wastewater, or desalinating water for drinking purposes.These plants are designed to remove iron and other impurities, ensuring safe and clean water for community use.Such systems often incorporate technologies like adsorption, filtration, and aeration to oxidize and remove iron particles. They are typically pre-fabricated for easy installation and require minimal maintenance.

School and community Water Filters – 100 GPD, 150 GPD, 300 GPD capacity

Integrating IoT-enabled devices with drinking water systems using Reverse Osmosis (RO) and Ultraviolet (UV) purification is transforming how we access clean water. RO removes dissolved impurities like salts and heavy metals, while UV treatment neutralizes harmful microorganisms without chemicals. Adding IoT technology allows real-time monitoring of water quality, predictive maintenance, and remote control of the system. Companies like Hydromaterials are pioneering these advancements, enhancing water safety and promoting sustainability. This fusion of technologies not only optimizes resource use but also holds promise for providing safe drinking water to communities worldwide. It’s fascinating how technology is reshaping such a fundamental resource.

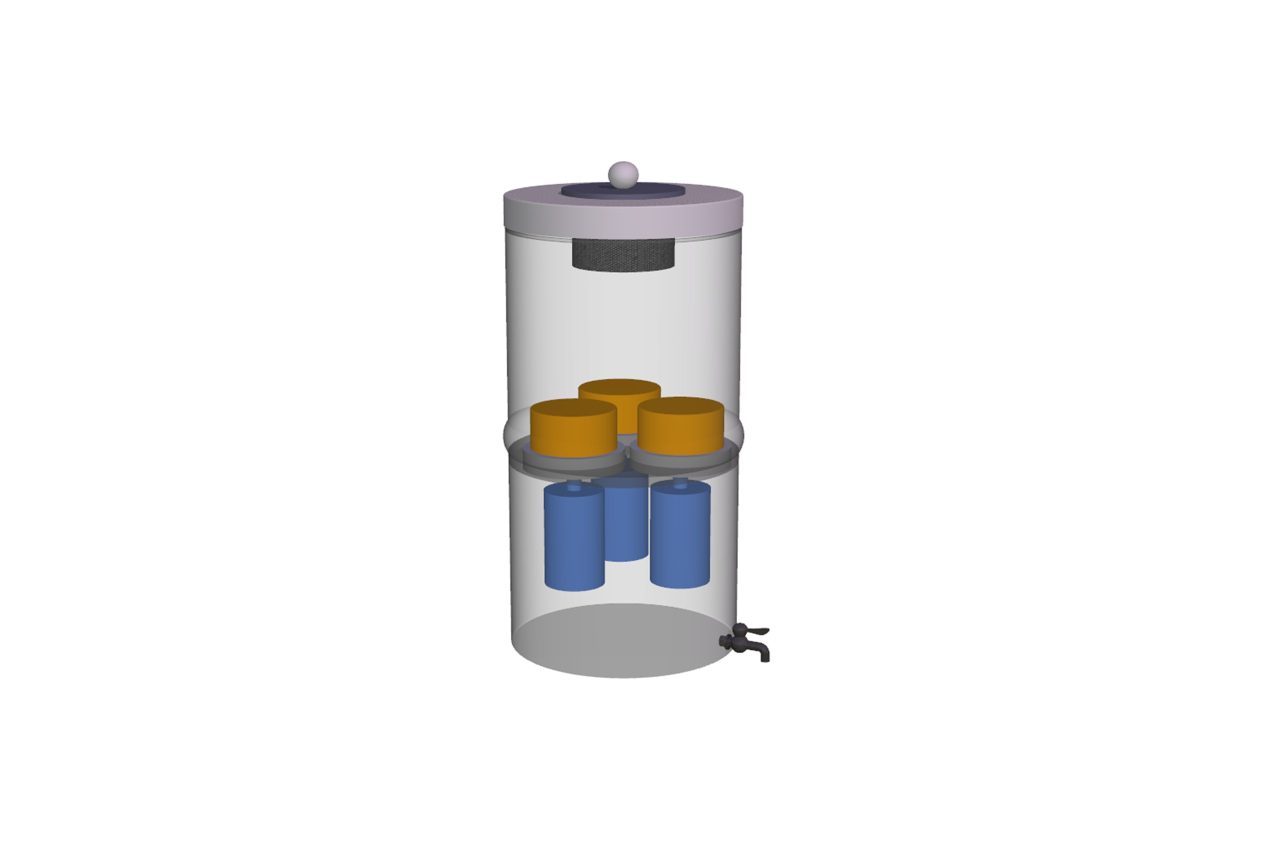

An affordable domestic water purification unit for Iron and Arsenic removal

Iron and turbidity removal by physical filtration (Developed by CSIR-immt). Arsenic removal by adsorption. The product included one raw water storage tank, one treated water storage tank kept on a stand along with purification cartridges. Material of construction is SS304. Food grade polypropylene is used for plastic components. Capacity is 11 L + 11 L. Mode of operation is Manual pouring of water, and gravity flow to treated water tank. No electricity required for operation. Rate of filtration is 8 L/hr at 260 mm water head.

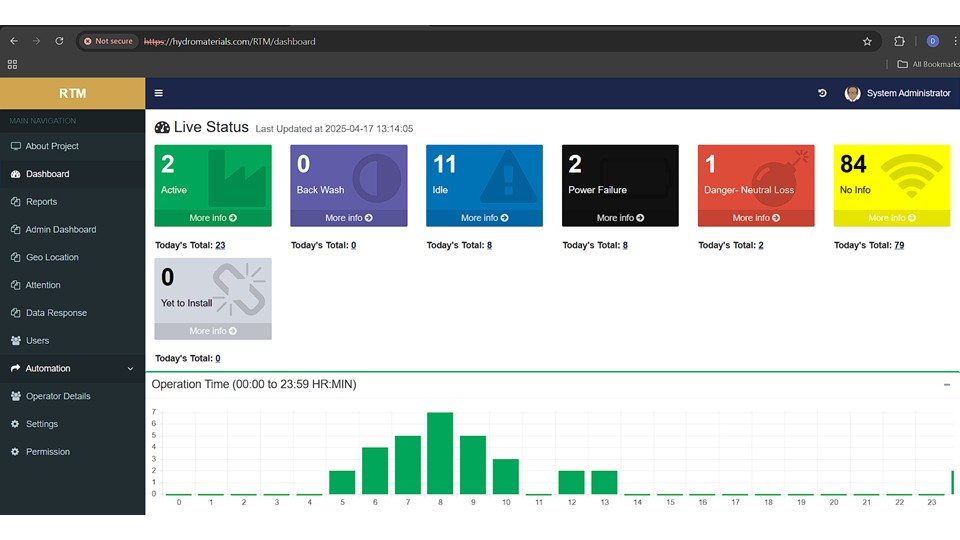

Cellular technology plays a pivotal role in remote monitoring and automation, especially in industrial and enterprise settings. It enables efficient communication between devices and systems, even in remote or hard-to-reach locations.They help collect data from automation equipment and transmit it to monitoring centers for analysis and fault detection.

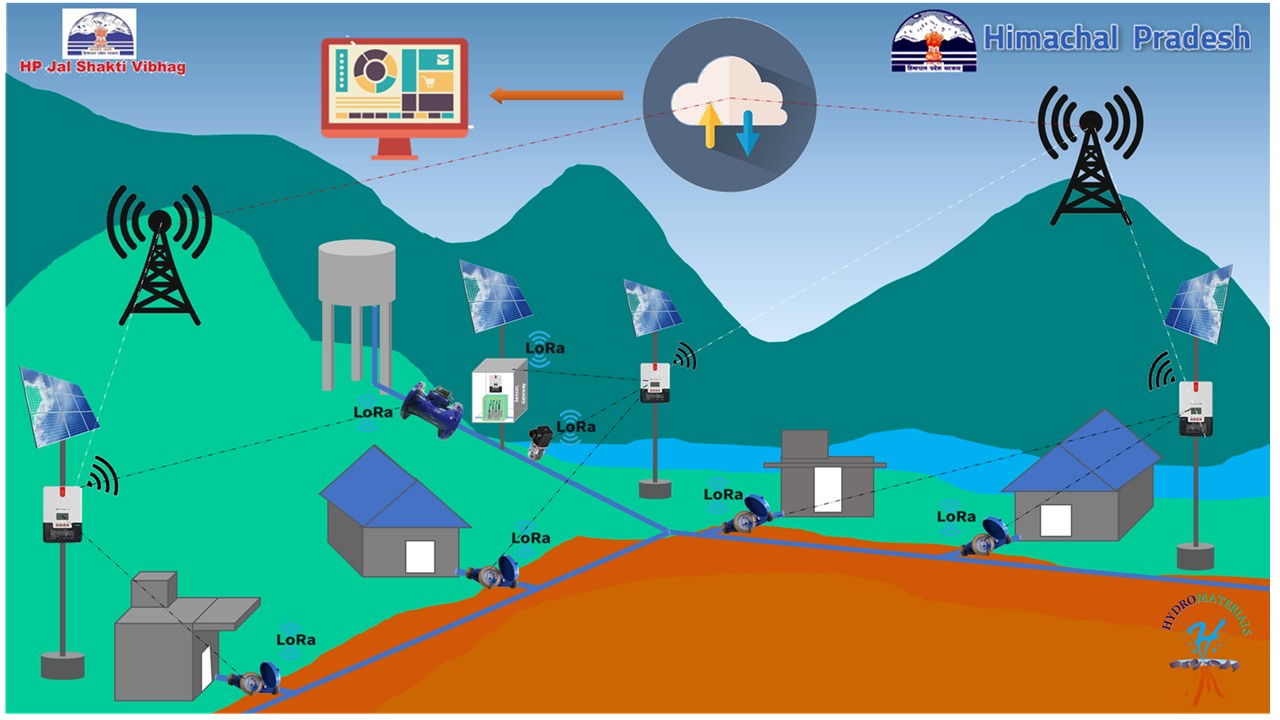

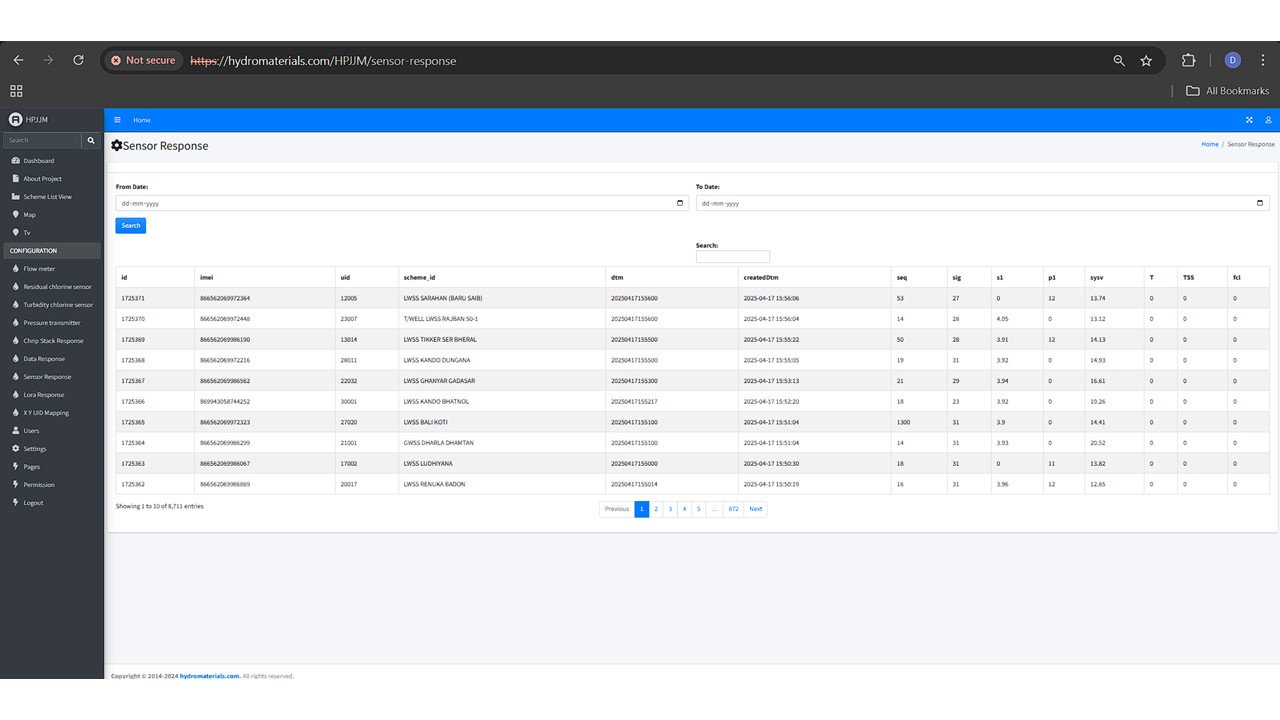

LoRaWAN (Long Range Wide Area Network) technology is a game-changer for remote monitoring and automation. It enables low-power, long-range communication, making it ideal for IoT applications across industries.LoRaWAN enables the wide-area deployment of smart water meters, allowing for easier monitoring of water consumption across large areas.These meters can measure water consumption at regular intervals and transmit data wirelessly via the LoRaWAN network.This data can be accessed remotely, eliminating the need for manual meter readings and providing real-time insights into water usage.

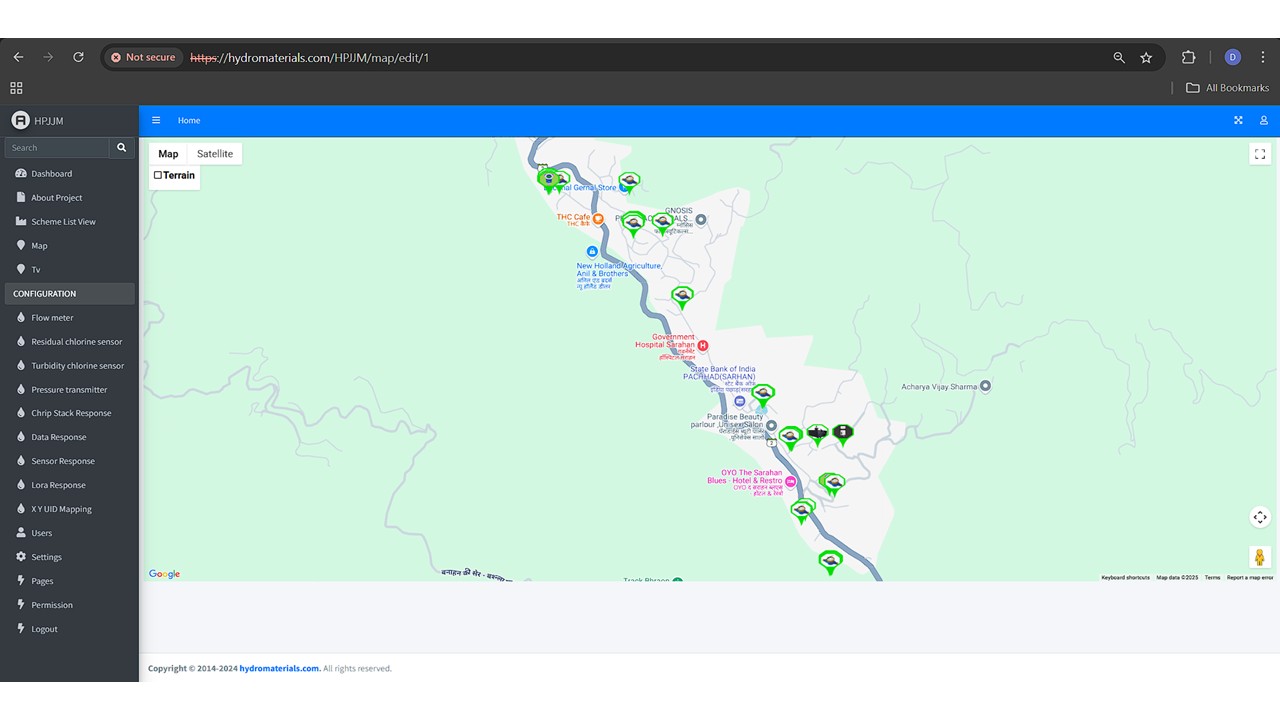

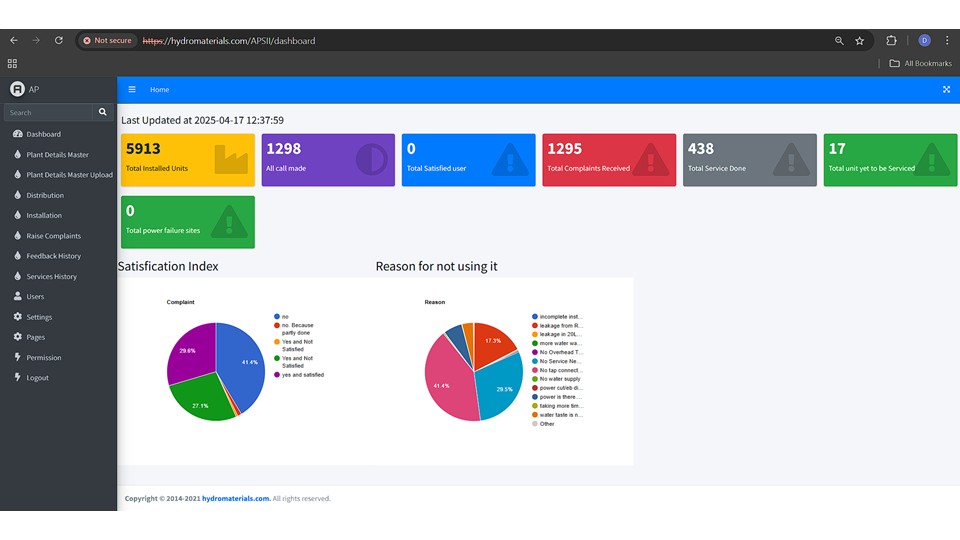

An IoT web application is a software program accessed through a web browser that allows users to interact with and control Internet of Things (IoT) devices remotely.