Our solutions and services

R&D

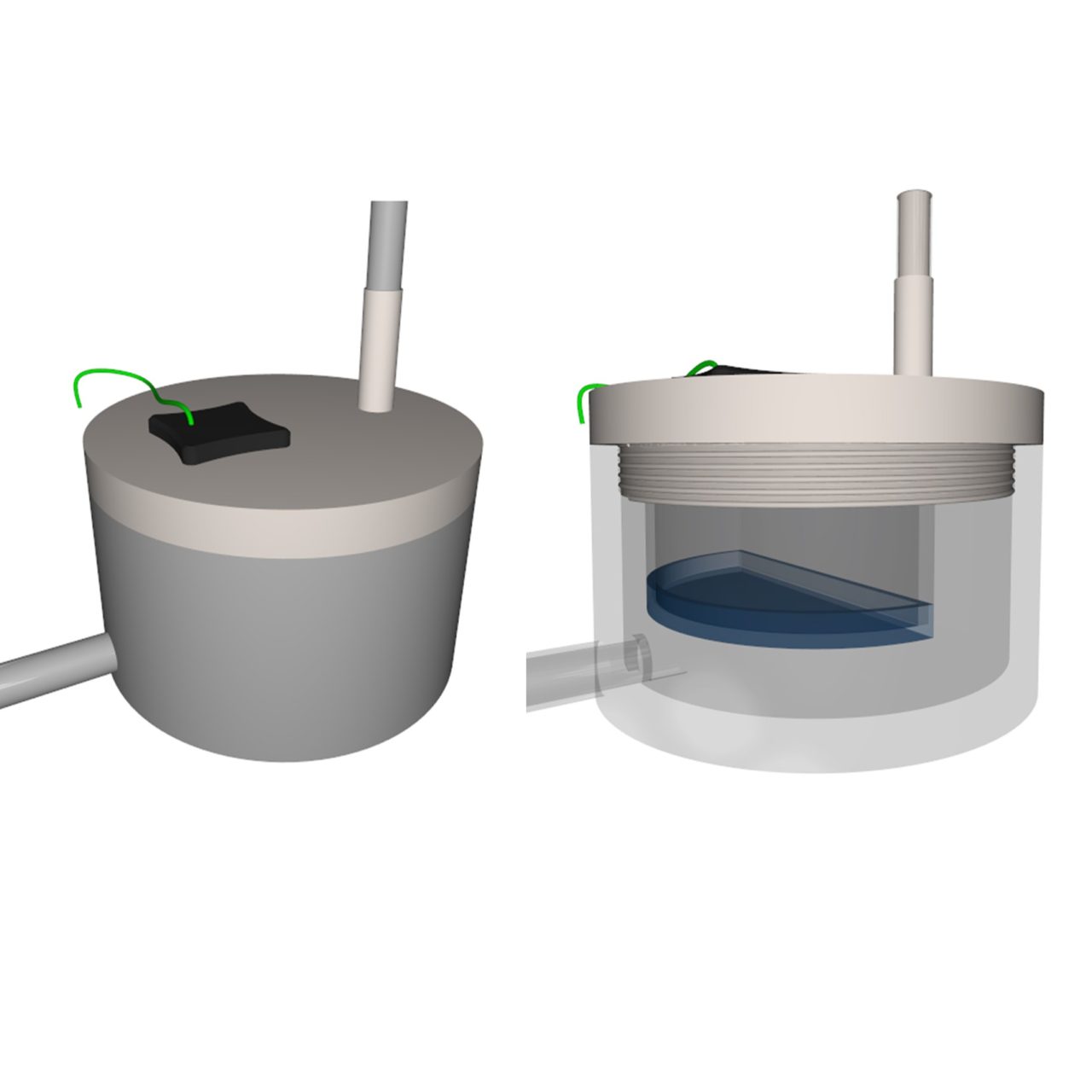

Our R&D focuses on developing and optimizing water purification technology using nanomaterials for adsorptive removal of anions and metals. Key areas include: nanomaterial synthesis and characterization, adsorption mechanism and kinetics studies, material optimization for enhanced performance, system design and prototype development; and field testing and validation, all tailored to address specific Indian water purification challenges.

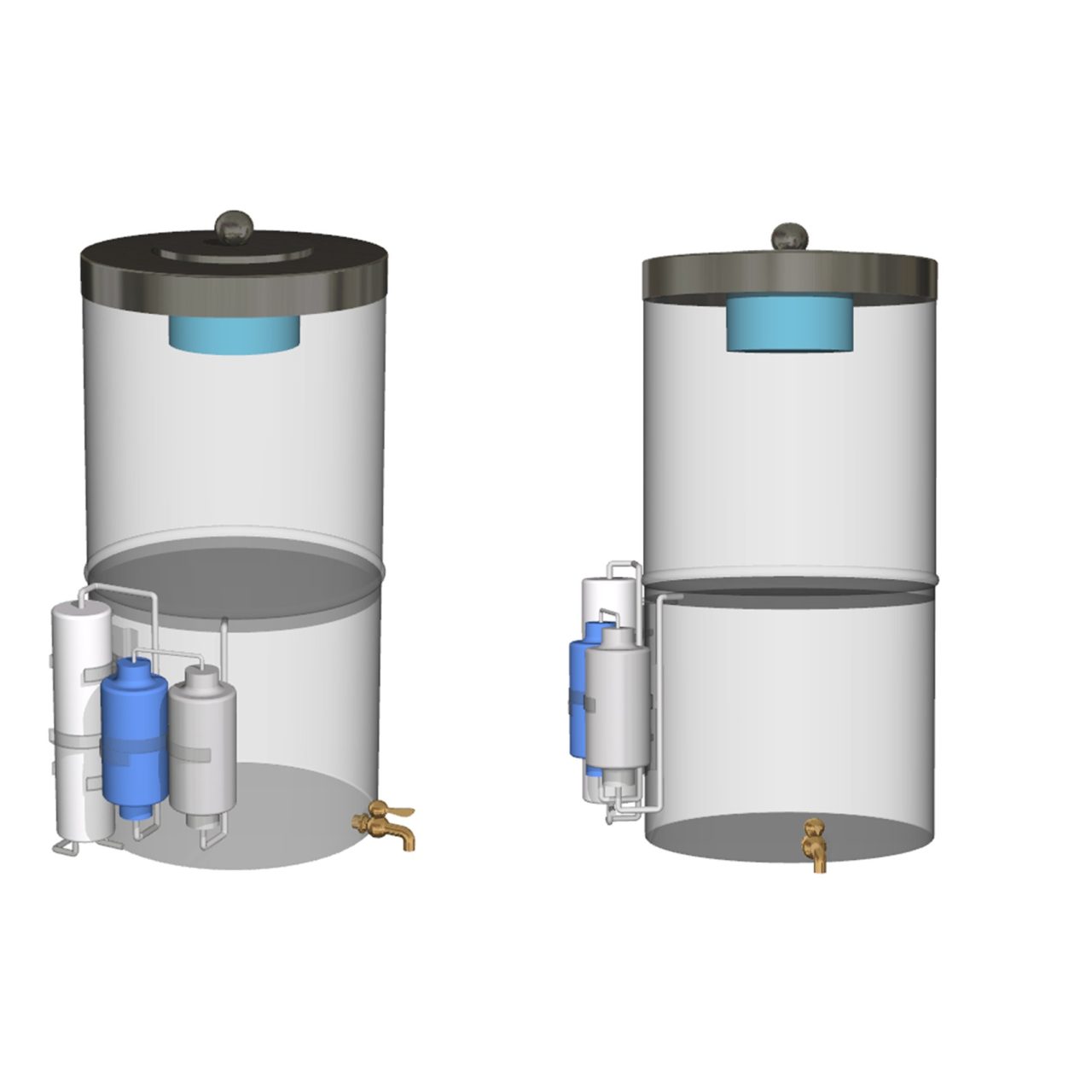

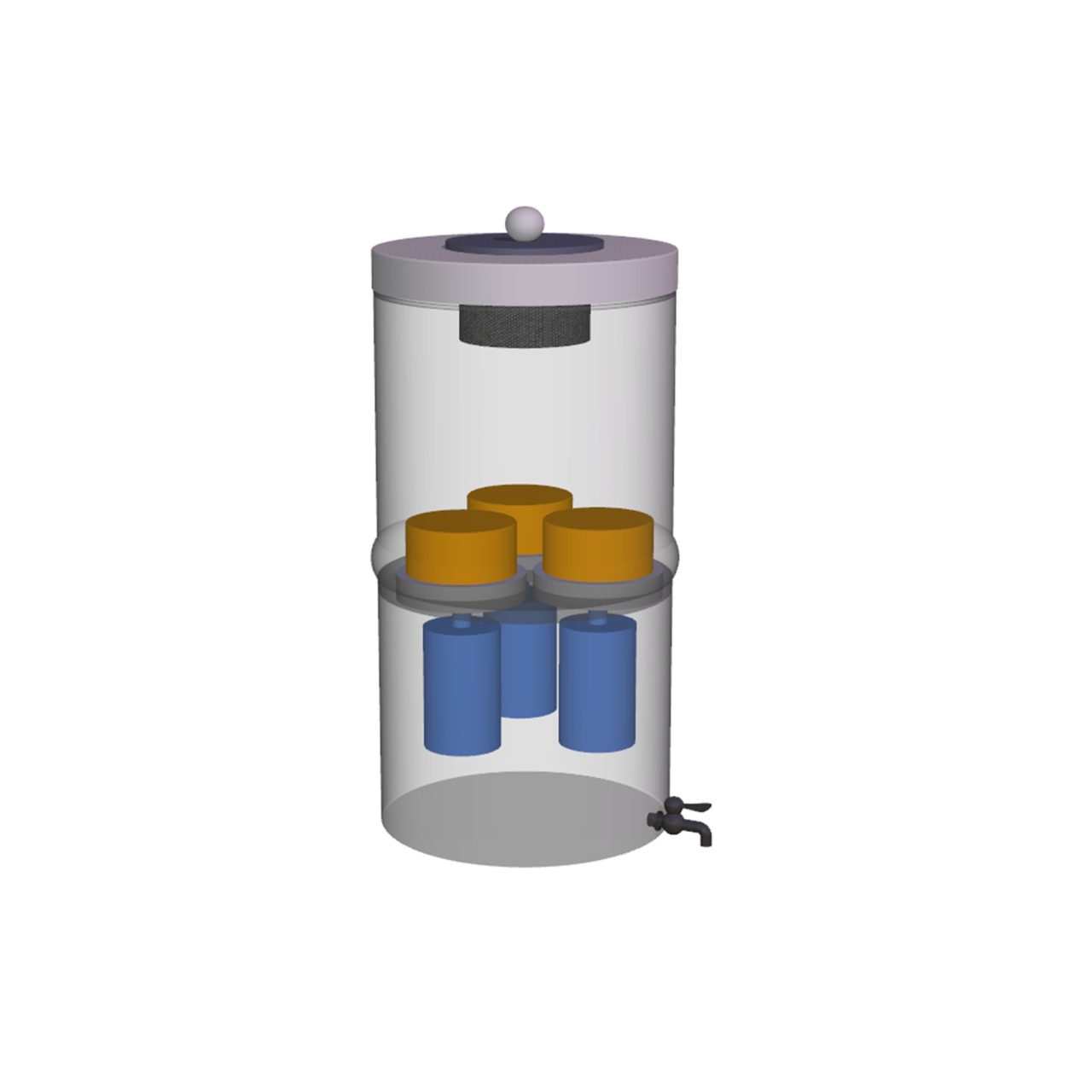

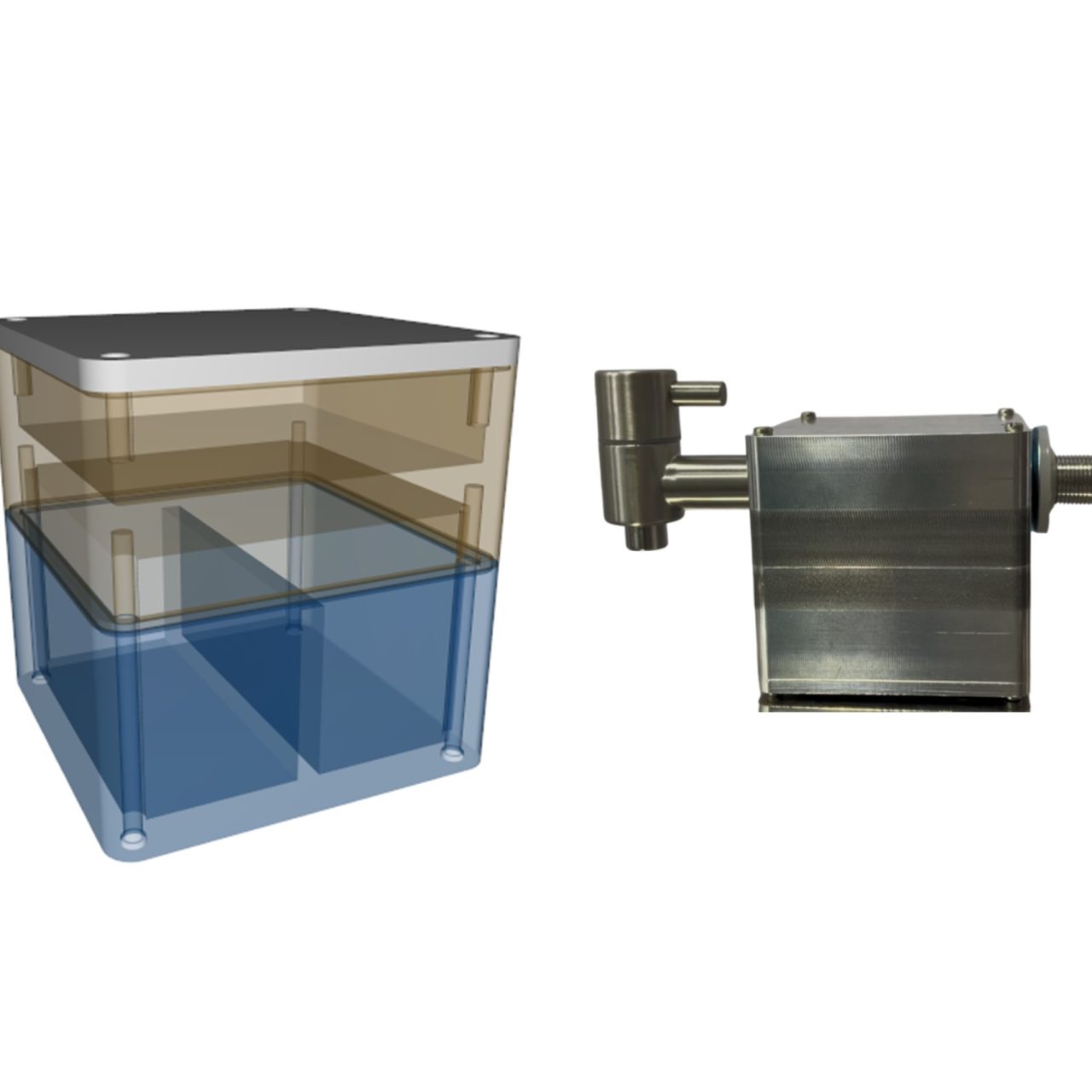

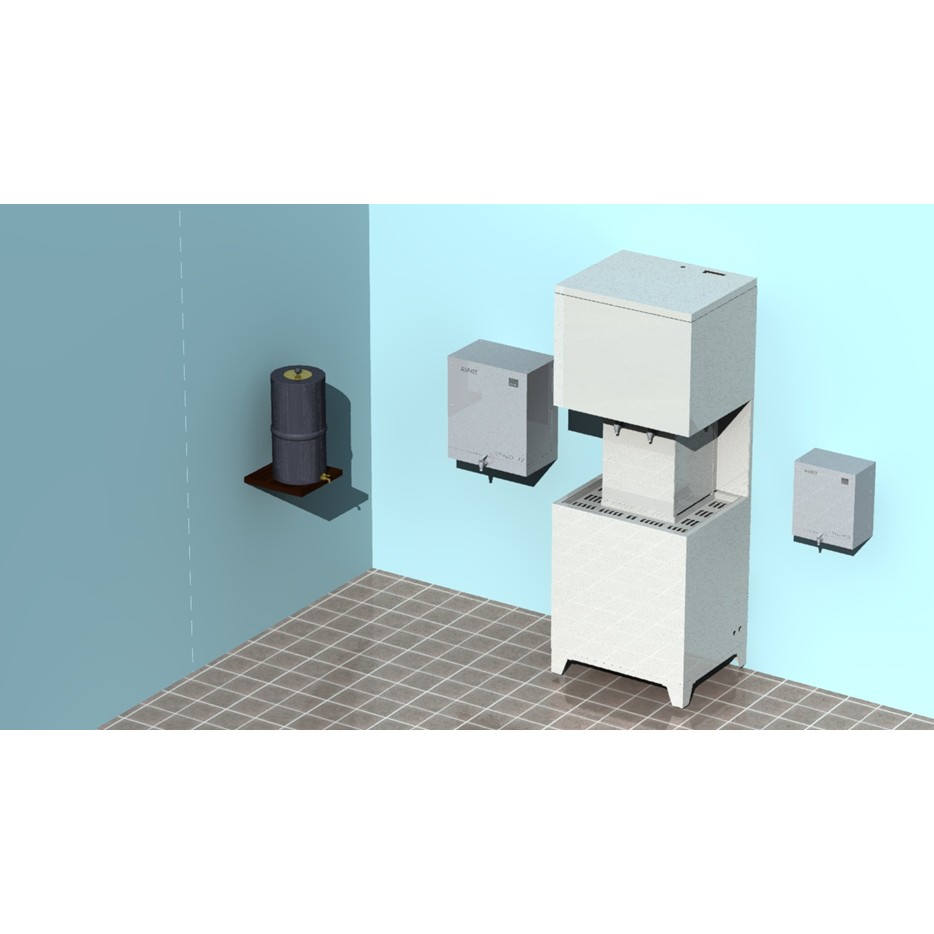

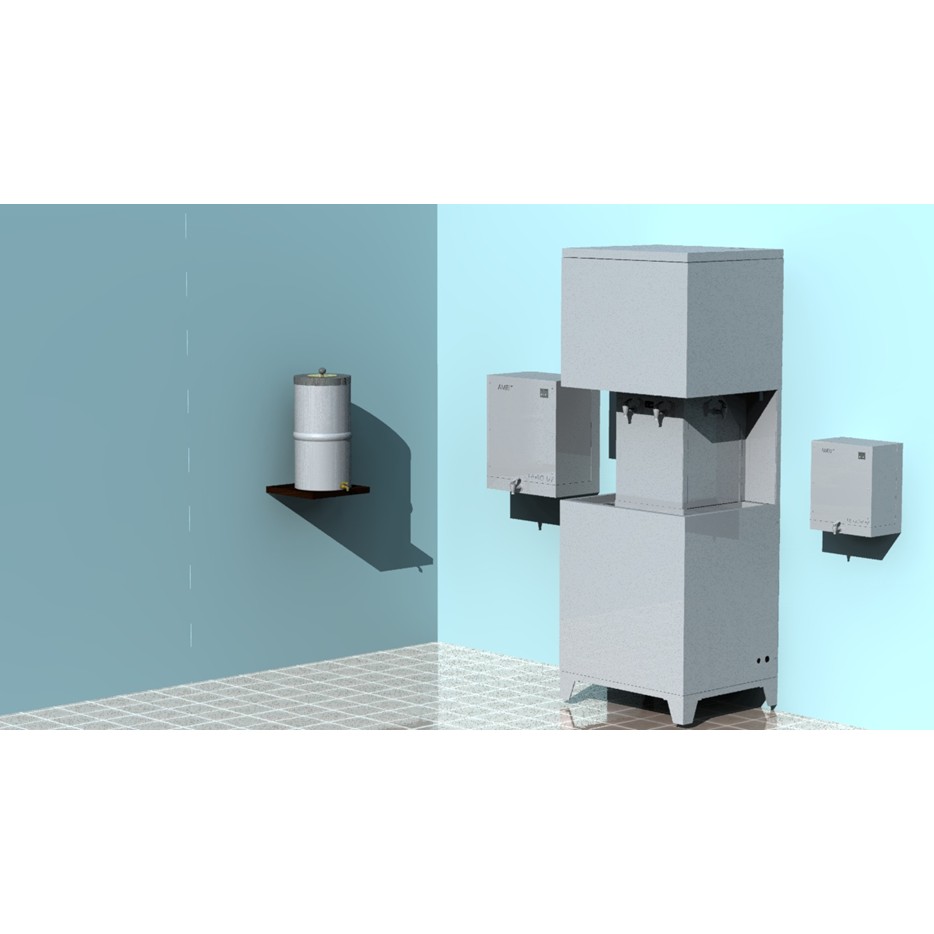

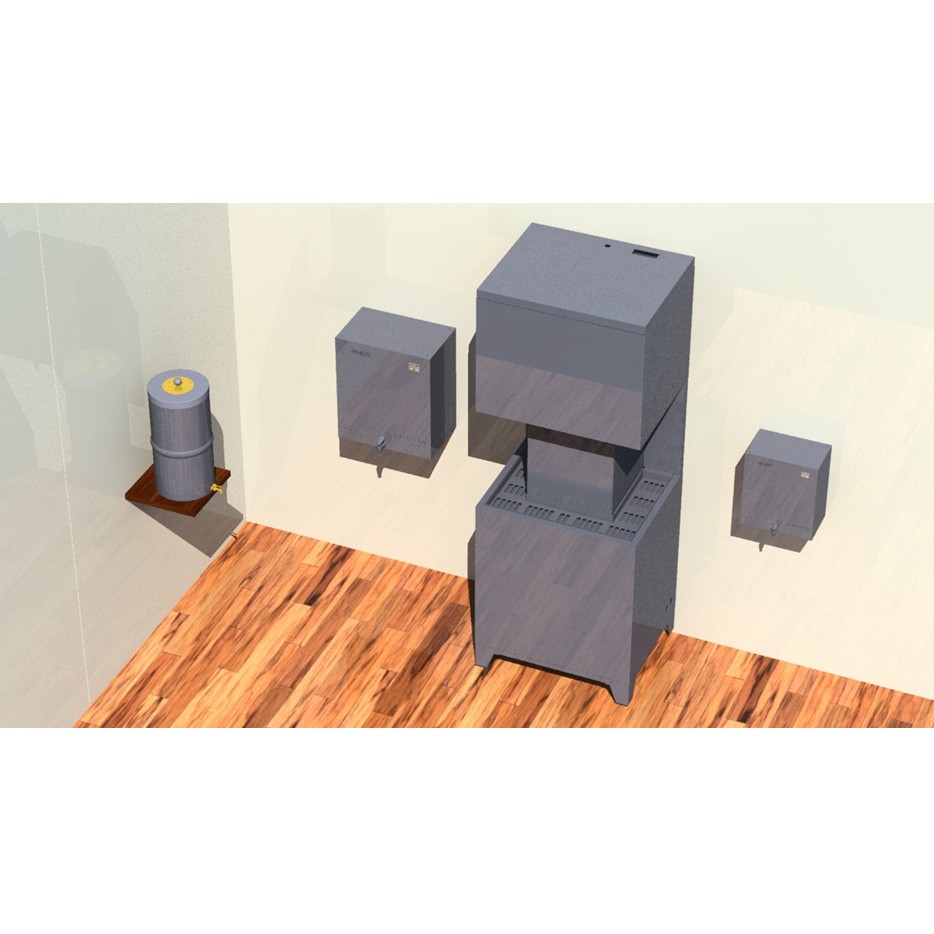

Design

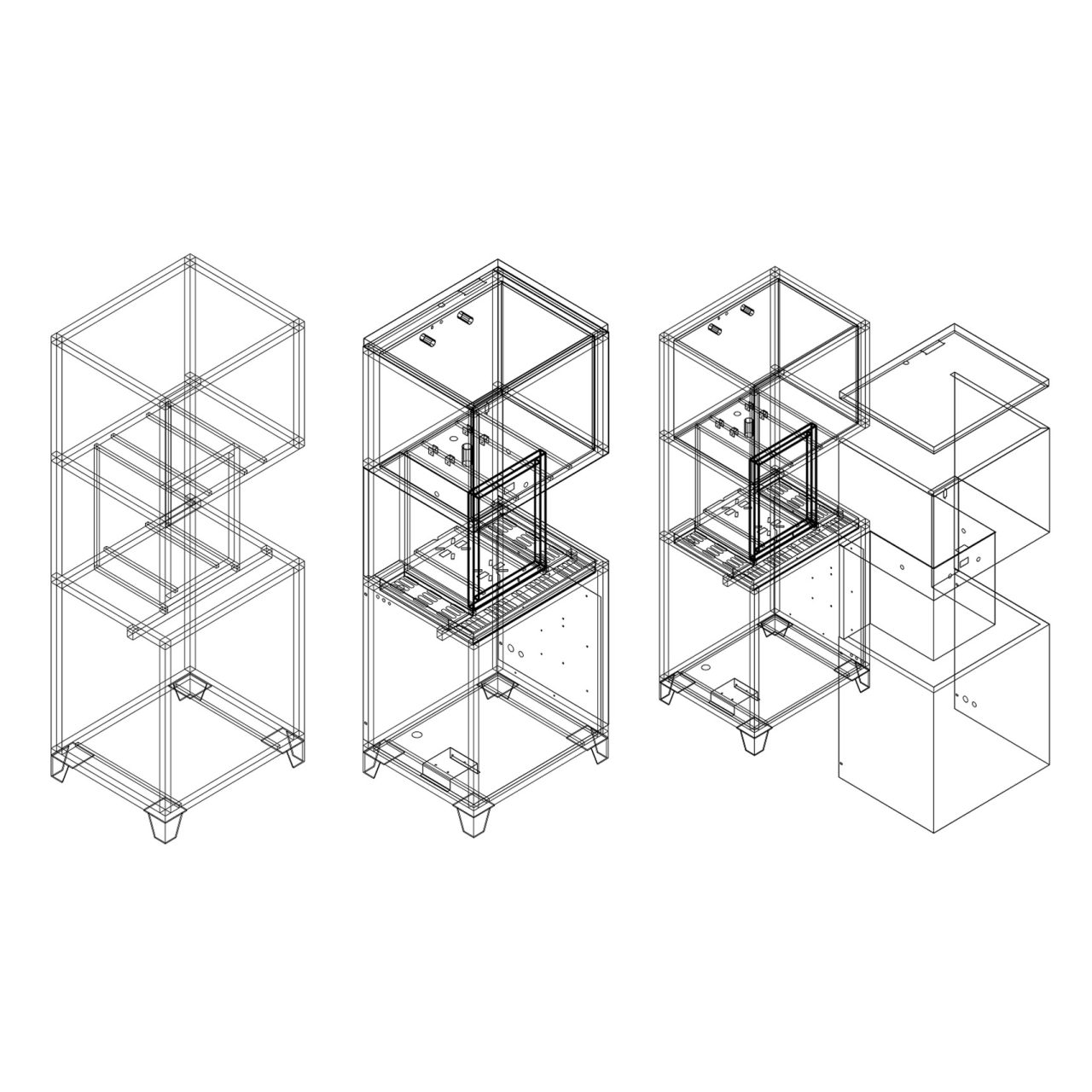

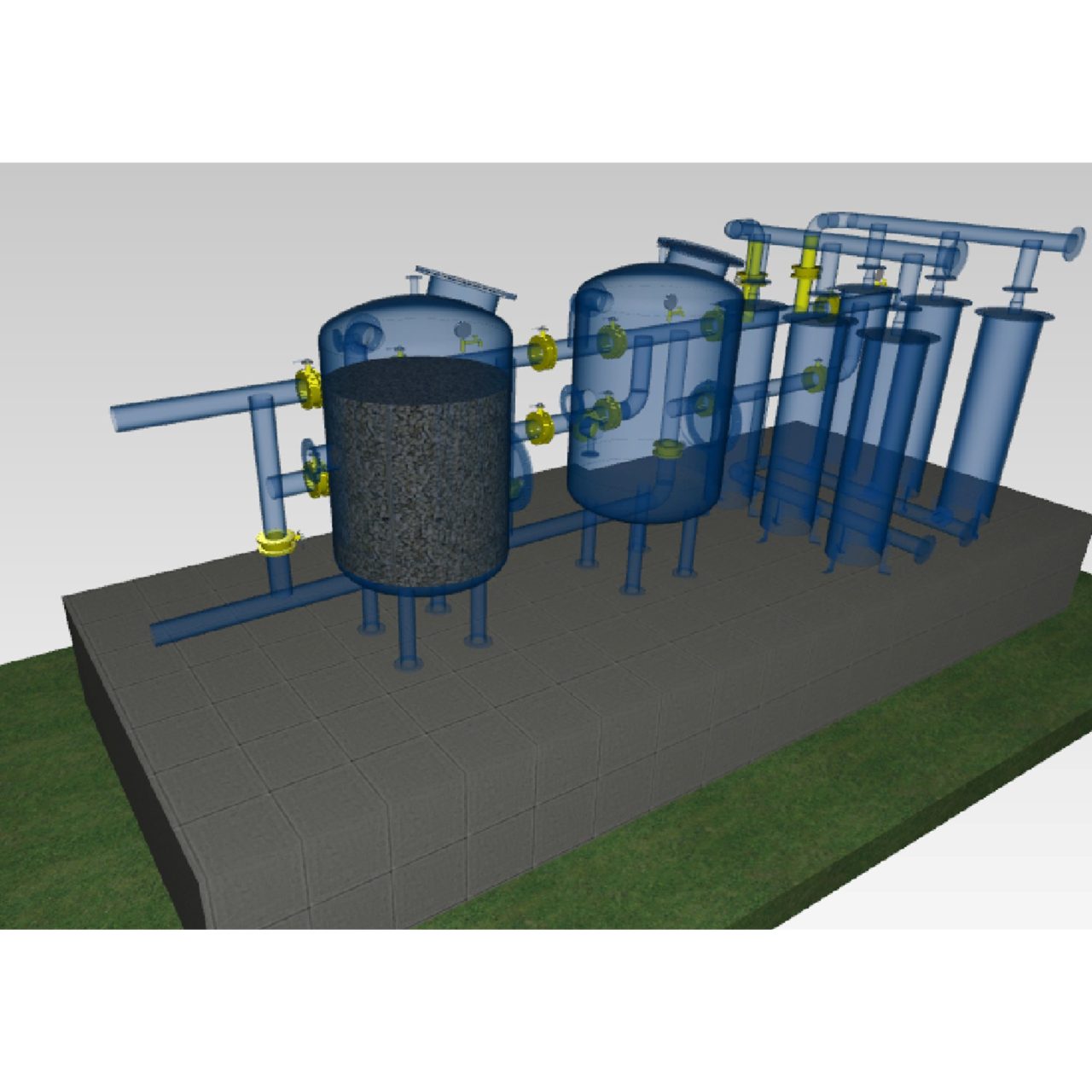

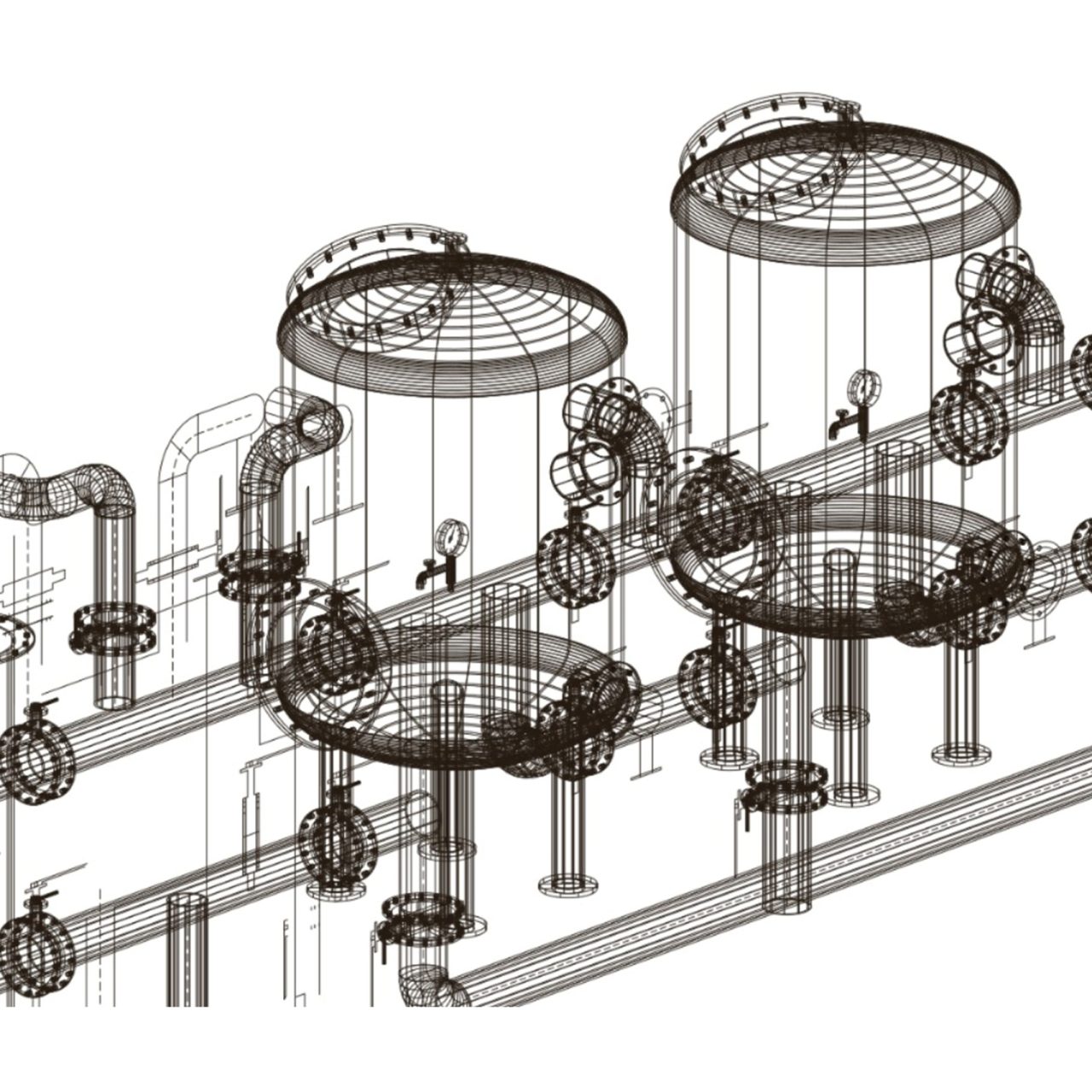

Design focuses on efficient adsorber configurations (packed/fluidized beds, membranes) optimized for contact time and flow. It integrates pre/post-treatment, emphasizes scalability and modularity, uses compatible materials, ensures ease of operation and maintenance, prioritizes cost-effectiveness, and incorporates safety features for nanomaterial handling.

Manufacturing

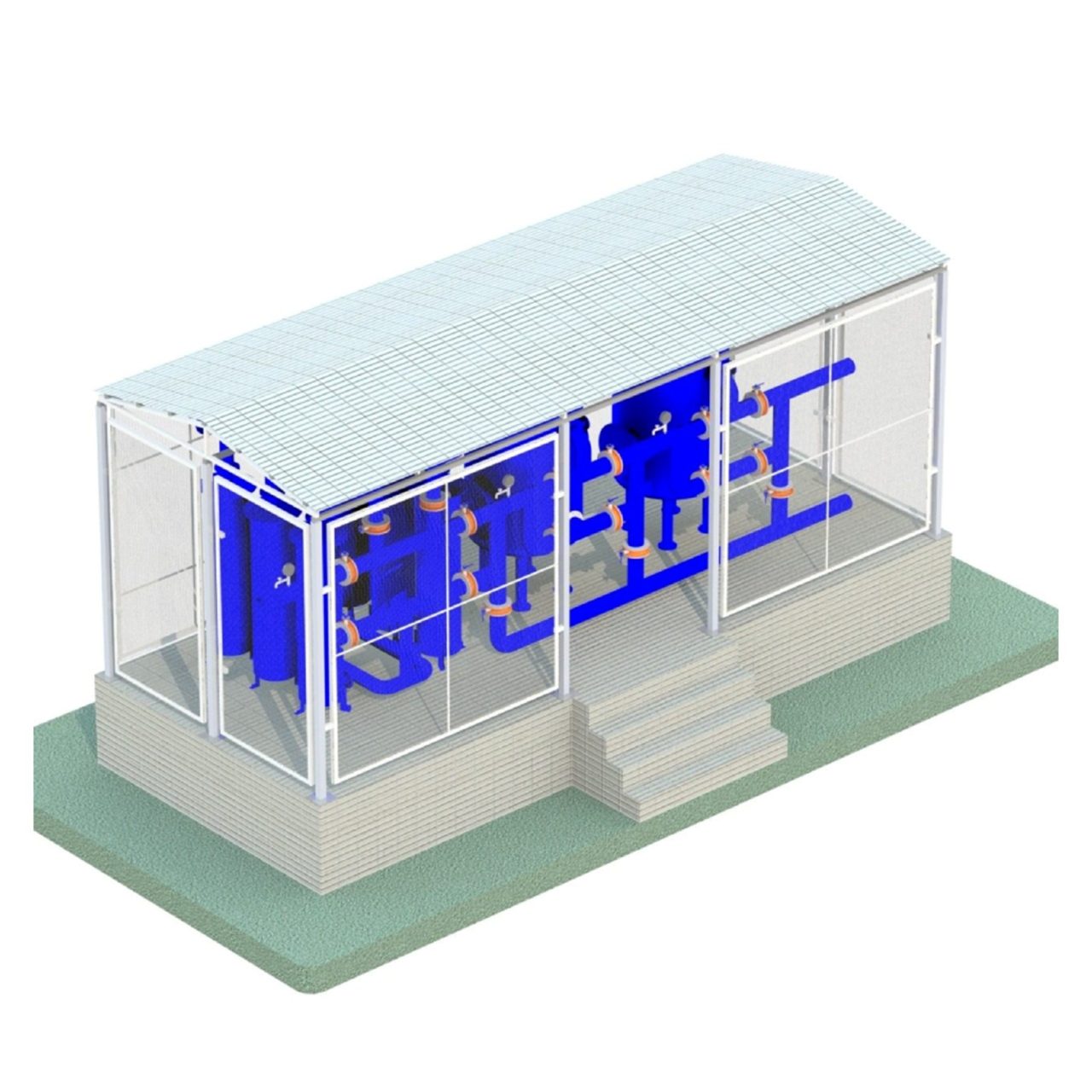

Manufacturing follows strict quality control, using high-quality materials and precise fabrication. Pipeline production uses durable materials and ensures leak-free conveyance. System integration involves careful hydraulic design and connection. IoT implementation enables remote monitoring and community management through a user-friendly interface. Rigorous testing and sustainable practices are employed throughout.

Automation

Automation optimizes system manufacturing and operation. Automated unit fabrication and pipeline production ensure quality and efficiency. IoT-enabled automation allows remote monitoring, control, data analysis, alerts, and community management tools. This minimizes human intervention, improves data accuracy, and enhances system reliability.

Our solutions and services

Cloud IoT Device Management

Cloud IoT Device Management securely connects, manages, and monitors AMRIT units. It enables remote configuration, real-time monitoring, control, OTA updates, and predictive maintenance. Data collection and analytics provide insights for optimization. This improves efficiency, security, reliability, and scalability while reducing costs.